The Imprudent Promise of Plastics

In the exciting post-World War II years, the prophet of plastics rightly foresaw an industrial boom centered around these new durable and versatile materials.

Before buying a mountain to settle into in Vermont, Dr. Joseph Davidson had studied chemistry, served in World War I, and worked at Union Carbide’s K-25 plant in Tennessee, a secret factory that produced enriched uranium for the first atomic bomb. By 1950, he was president of Union Carbide’s chemicals division that held patents for laminated safety glass, vinyl compounds, and the trusty old plastic, Bakelite.

Arthur Baum wrote about the inventor and plastics dynamo in this magazine in 1950’s “The World Goes Plastic,” focusing on Davidson’s estate on Mount Equinox. High on the Vermont mountain, a vast property Davidson had steadily acquired throughout the ’40s, were his home and the Sky Line Inn. The inn exuded a “certain soul-disturbing significance,” according to Baum, for the omnipresence of plastics in its construction: “Thus the inn is a sort of challenging physical demonstration of the young plastic industry’s claim that its materials are already an improvement on nature.”

The praise heaped upon plastics — and the brilliant chemists behind them — was pervasive in the postwar years. The versatility of these thousands of new polymers presented a seemingly infinite set of possibilities for industry, medicine, and even a new American way of life. Innovators like Davidson seemed to have all the answers in the new plastic boom. All except one, of course: where will it all go once we’re finished with it?

The American “plastic age” began with Bakelite. First created in 1907 by Leo Baekeland, the “material of a thousand uses” came to be when the Belgian chemist found a way to control the reactions of phenol and formaldehyde to produce a moldable plastic. Bakelite could be used to make bowling balls, castanets, goggles, paper weights, and piano keys. A 1923 ad in The Saturday Evening Post boasted of the new plastic’s imperviousness to the elements that made it ideal “for your daughter’s jewelry and the ponderous dreadnaught.” Unlike old-news Celluloid, Bakelite held up to heat and electricity, making it ideal for electronics, weaponry, and everything in between. “It’s part of your everyday life!” a 1924 ad announced.

In 1939, Union Carbide bought the Bakelite Corporation. Chemists from across the complex international world of plastics were developing new polymers throughout the ’30s and ’40s, some of which would become staples of manufacturing. Nylon, polyethylene, and polystyrene were all perfected during this period. While Bakelite was a thermosetting plastic — meaning it was irreversibly hardened and shaped — these new thermoplastics could be pliable again when reheated.

The excitement around plastic’s endless prospects drove innovation for its own sake, as Jeffrey L. Meikle writes in American Plastic: A Cultural History: “The new generation of chemists, on the other hand, worked outward from chemical discoveries to the marketplace. When they found something of interest, they looked for ways to commercialize it. They were driven not so much by market demand as by the pressure of supply, an overabundance of chemical raw materials waiting to be exploited.”

The public wasn’t exactly clamoring for single-use plastics, but they were on their way nonetheless.

In 1950, Baum’s article stressed the plastic industry’s desire for a public educated in the subtleties of its products. Union Carbide and its competitors wanted consumers to know their acrylics from their alkyds just as they could tell cotton from linen. Manufacturer trade names for various plastics came and went. Some of them stuck, like DuPont’s “Nylon” and Dow’s “Saran,” and others, like American Cyanamid Company’s “Beetle Plastic,” were non-starters. At some point in the years following, the goal of branding polyethylene as some luxury material dropped off in lieu of a new one: teach the people how to throw it all away.

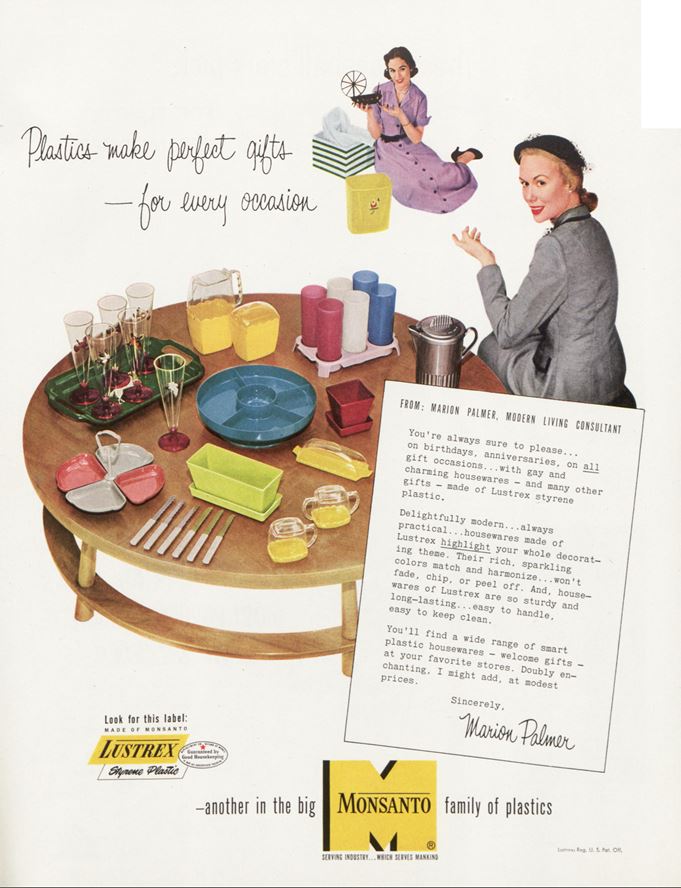

The Great Depression had instilled a sense of frugality and reuse into the populace. In the late ’40s and early ’50s, advertisements for plastic products focused on their design and durability. Dow’s “Styron” added “new color, beauty, and serviceability” to kitchenware and toys, and Monsanto’s “Lustrex Styrene” made “cheerful, convenient, and practical picnicwares” that were easy to clean. Disposability wasn’t yet a selling point, because it was more desirable to have a product that lasted.

That changed, however, in the ’50s. A now-infamous Life magazine spread in 1955 welcomed the new era of “Throwaway Living” with a photo of a family gleefully tossing their disposable napkins, plates, and utensils into the air, rejoicing in the reduced cleaning time. The move toward single-use plastics wasn’t a random occurrence. It was a calculated strategy by the industry in the interest of protecting its bottom line.

As environmental scientist Max Liboiron writes in “Modern Waste as Strategy,” “The truism that humans are inherently wasteful came into being at a particular time and place, by design.” That time and place, according to Liboiron, was the Society of the Plastics Industry’s New York conference in 1956. Lloyd Stouffer, editor of Modern Plastics, Inc., stood before the trade group and declared, “the future of plastics is in the trash can.” His statement was to be taken literally: if plastic manufacturers wanted to ensure a steady demand for their products, they needed to encourage a culture of disposability. The industry needed to convince consumers that plastic wasn’t too good to be thrown away.

Seven years later, a pleased Stouffer addressed the conference in Chicago: “It is a measure of your progress in packaging in the last seven years that this remark will no longer raise any eyebrows. You are filling the trash cans, the rubbish dumps and the incinerators with literally billions of plastics bottles, plastics jugs, plastics tubes … The happy day has arrived when nobody any longer considers the plastics package too good to throw away.” In 1950, 2 million tons of plastic was being produced globally. By 1963, it was 13 million tons. Now, it’s about 400 million tons.

Where all that plastic would go once we were finished with it began to raise questions in the 1960s. Throughout the decade, scientists began to notice plastic particles being ingested by seabirds. First in the prions of New Zealand, then in the petrels of Newfoundland. In 1966, 74 of 100 dead albatross chicks in the northwest Hawaiian islands were found to have an average of 2 grams of plastic in their stomachs. In 1972, two papers in Science sounded the alarm over plastic particles — particularly polystyrene pellets — in the Atlantic Ocean. The papers sparked concern over plastic marine litter and suggested that the toxicity of plasticizers and polychlorinated biphenyls (PCBs) could be hazardous to marine life and, in turn, human life.

Since those discoveries, our knowledge of the pervasiveness of plastic pollution has grown exponentially, just as our consumption of plastics has. In Plastic: A Toxic Love Story, author Susan Freinkel writes, “Our feelings toward plastic are a complicated mix of dependence and distrust — akin to what an addict feels toward his or her substance of choice.” Freinkel says that people just weren’t thinking about environmental issues in the 1950s, when plastic production was ramping up. “What’s different now,” she says, “is the massive volume of plastic production and the resulting mammoth amount of plastic trash, the new technologies that have allowed us to see and spread images of how much ends up in the oceans; the research efforts to that, and the utter breakdown of the recycling system, such as it was. It’s kind of a perfect storm for heightening awareness and concern — and hopefully real solutions.”

Professor Richard Thompson, a marine biologist at University of Plymouth, echoes concerns over the current massive consumption of plastics, especially since 40 percent of it is single-use. He says, “We knew [in the ’50s] that carbon resources were finite, and we also knew that space to handle waste was finite as well. The industry needlessly drove the linear use of that resource to waste.” Thompson says the end of life of a product should be considered at the design stage of everything, from textiles to packaging. Given the last 70 years or so of mounting plastics production, he says, “It would appear to be a deliberate attempt on the part of industry to enhance demand by encouraging wastefulness.”

In 2004, Thompson coined the term “microplastics” to describe the small particles of plastic that litter the oceans. While many plastic products take centuries to completely degrade — if at all — they do break down from mechanical processes into small, even microscopic, pieces. While the starches that hold such “biodegradable” plastics together will themselves biodegrade, they leave behind tiny particles that will be with us for a long time. Last week, studies from Environmental Science & Technology and World Wide Fund for Nature showed that these microplastics are making their way into our bodies. On average, we are ingesting about 50,000 particles of plastic each year, according to the research. The implications of eating and breathing all those microplastics are yet unknown.

The durability of plastics, once a celebrated characteristic, has turned out to be a curse of epic proportions.

Dr. Joseph Davidson’s “plastic mecca” on Mount Equinox was built when his brash new industry proclaimed its vinyls and resins to be more lasting and more exciting than traditional building materials. The Bakelite tiles and vinyl coverings in the buildings on Davidson’s estate would have lives measuring “in the hundreds of years,” according to Baum’s 1950 article. But, Davidson’s home, “Windswept,” and his Skyline Inn have since been torn down. In his later years, Davidson donated his many acres on Mount Equinox — little by little — to the only group of Carthusian monks in the United States. They settled on the mountain and built a monastery that opened shortly after Davidson’s death. Given the Carthusians’ penchant for simplicity, their charterhouse is made entirely of granite.

Featured Image: Union Carbide Corporation, The Saturday Evening Post, August 27, 1955