In 1964, NASA ordered the construction of a vast structure capable of assembling space vehicles to send to the moon. Over five decades later, that same building is gearing up to send them to Mars.

NASA publicly displayed their Moon to Mars initiative in May with the tagline “We Are Going.” To achieve the goal of reaching Mars, the first step is building infrastructure on the surface of the moon.

Sending humans back to the moon to build a sustainable launching point for Mars led NASA to develop the Space Launch System (SLS), a rocket capable of evolving over time to launch more than six missions of cargo and astronauts; the maiden voyage will blast-off in the summer of 2020.

NASA’s “We Are Going” video

50 years ago, the Apollo 11 mission landed the first humans on the moon, and today, the same facility where Apollo was built is being used to craft modern machinery to reach the next step with Artemis 1 — named after the goddess of the Moon and twin sister of the mythological god Apollo.

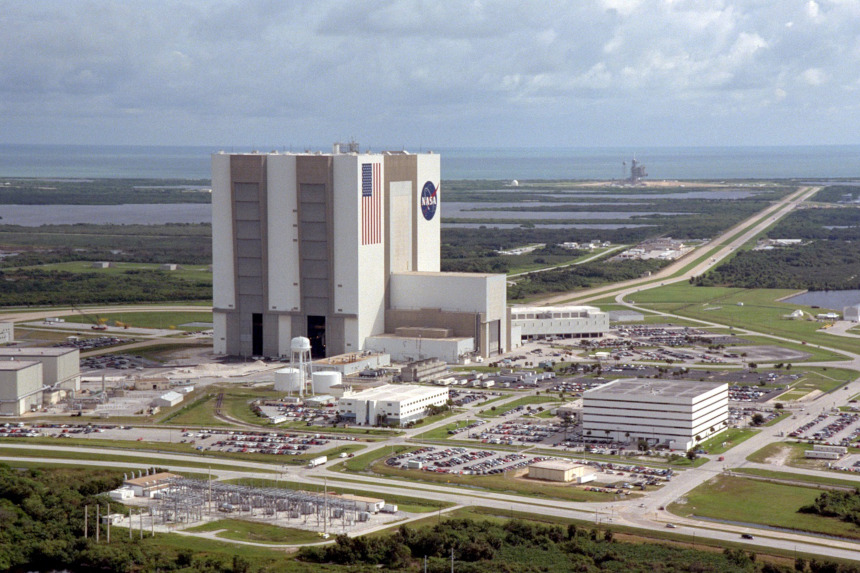

The two missions share more than just name, however; both are pioneering a new age of spacecraft construction. The NASA Vehicle Assembly Building (VAB) — located at the Kennedy Space Center in Brevard, Florida — was constructed in 1966 to assemble the Saturn V rocket that carried the Apollo 11 mission crew. The VAB is one of the world’s largest buildings by volume, taking up 36,878 cubic miles of hangar space.

The massive structure closed down in 2014 for remodeling to prepare for the construction of the Orion rocket, the first piece of Artemis 1, and the SLS. The VAB is the birthplace of components for all NASA missions, including rockets, space shuttles, and satellites. Although the building was constructed in the ’60s, continual updates have made it a marvel of modern technology.

Before the 2014 remodel, rockets were built from platforms that surround the construction bays. As of the most recent update, the building has modular platforms in place that can move up, down, and around the rockets, meaning the necessary machinery can get in closer, be more precise, and take less time to assemble the pieces of the SLS.

On June 3, NASA reported that their workers at the VAB reached a critical checkpoint in the development of the first piece of the SLS. The first segment of the rocket’s main core stage has been nearly completed. The 190 feet tall core rocket stage is the first of six that will provide the thrust necessary to launch Orion to the moon. It is the largest rocket stage constructed since Saturn V.

The main core stage, as well as four supplementary boosters, will produce over 8.8 million pounds of thrust to propel the astronauts out of the Earth’s exosphere. By comparison, the Saturn V rocket required only 7.7 million pounds of thrust. The large scale improvement in rocket systems will allow Orion to reach the moon faster and with more cargo.

Through the 465-foot-high doors of the VAB come some of the world’s most advanced pieces of technology, but the building itself is certainly a unique piece of American industry. The building’s initial construction workers “grew up in work clothes and graduated in modern math and computerized controls,” as NASA put it in a promotional video. Building the VAB supplied jobs for more than 2,000 Americans in the construction, engineering, and steel industries.

The VAB’s large stature is necessary to accommodate projects that are big enough to overcome the challenge of space travel, but with that much volume comes unforeseen consequences. The air conditioning system in the VAB is state of the art, not to cool the workers or the rocket, but to regulate the atmospheric conditions in the hangar. The ceilings of the hangar are so tall that, if left unchecked, clouds would form underneath them and, in the right conditions, bring down rain upon the spacecraft. Workers from the VAB

The physical size of the massive building is miniscule compared to the importance of the monumental missions that its products complete. The Artemis missions, SLS, and Orion are the key pieces to 2020’s space travel, both for the United States and for the world. In a statement about “Explore Moon to Mars,” NASA administrator Jim Bridenstine said, “President Donald Trump has asked NASA to accelerate our plans to return to the Moon and to land humans on the surface again by 2024. We will go with innovative new technologies and systems to explore more locations across the surface than was ever thought possible. This time, when we go to the Moon, we will stay. And then we will use what we learn on the Moon to take the next giant leap — sending astronauts to Mars.”

As the United States continues to lead the charge for space exploration with help from the leading powers of the globe, the heart of international space technology is located in the hangar of the VAB. As it was described by NASA at its construction, “space and time are related in this great new age, but construction and time have always been married.” The VAB was designed with the future of humanity in mind and it continues to live up to that expectation. At its grand opening, it had the task of building Saturn V, which was like planting an acorn for the programs that followed; today, as shown by the technological advancements made to accommodate the construction of Artemis and the SLS, mighty oaks have grown.

Featured image: The VAB (NASA)

Become a Saturday Evening Post member and enjoy unlimited access. Subscribe now